Three aircraft 1 2 and 3 arrive successively at ten minute intervals ? [ Professional DGAC ]

Question 28-1 : 1 then by mutual consent 2 and then 3 1 and then by mutual consent to 3 1 until the completion of operations 1 then by mutual consent 2 until the completion of operations

(1), then by mutual consent (2) and then (3).

(1), then by mutual consent (2) and then (3). Icao annex 12 search and rescue .contracting states shall establish a rescue ?

Question 28-2 : In each search and rescue region at every ats facility at every international airport if they are adjacent to the sea

In each search and rescue region.

In each search and rescue region. Search and rescue signals .what is the meaning of the symbol 'lll' in the ?

Question 28-3 : Operation completed we are returning to base we have found all personnel we have only found some survivors

Operation completed.

Operation completed. How are search and rescue regions in remote areas organised ?

Question 28-4 : By regional air navigation agreements they are not organised as they are too inaccessible by iata search and rescue committee by icao search and rescue committee

By regional air navigation agreements.

By regional air navigation agreements. Search and rescue signals .a team of rescuers is searching for an aircraft that ?

Question 28-5 : We are not able to continue returning to base we have found only some personnel require medical assistance havve divided into two groups each .proceeding in direction indicated

We are not able to continue, returning to base.

We are not able to continue, returning to base. Search and rescue signals .the meaning of an x displayed by survivors on the ?

Question 28-6 : Require medical assistance require food and water require assistance need protective clothing

Require medical assistance.

Require medical assistance. Search and rescue – what does the ground air visual signal 'x' as used by ?

Question 28-7 : Require medical assistance require assistance no or negative or affirmative

Require medical assistance.

Require medical assistance. Those portions of the high seas or areas of undetermined sovereignty for which ?

Question 28-8 : On the basis of regional air navigation agreements those vast areas cannot be serviced determined by icao’s search and rescue committee determined by easa’s search and rescue committee

On the basis of regional air navigation agreements.

On the basis of regional air navigation agreements. The unit responsible for promoting efficient organisation of search and rescue ?

Question 28-9 : Rescue co ordination centre rcc flight information centre fic international alerting centre inac area control centre acc

Rescue co-ordination centre (rcc).

Rescue co-ordination centre (rcc). Whenever a distress transmission is intercepted by a pilot in command of an ?

Question 28-10 : Acknowledge the distress transmission and record the position of the aircraft in distress if given record the position of the transmission and proceed according to the flight hold at the position and coordinate the sar operation enter into a holding pattern and wait for instructions

Acknowledge the distress transmission and record the position of the aircraft in distress if given.

Acknowledge the distress transmission and record the position of the aircraft in distress if given. If the first aircraft to reach the scene of an accident is not a search and ?

Question 28-11 : Take charge of on scene activities of all other arriving aircraft leave the area to avoid hampering subsequent search and rescue activities overfly the wreckage every 10 minutes searching for any surface to air visual signals remain in the area overflying the scene of the accident at a height of 1000 ft on a north south heading

Take charge of on-scene activities of all other arriving aircraft.

Take charge of on-scene activities of all other arriving aircraft. In accordance with annex 12 what does the ground air visual signal code lll ?

Question 28-12 : Operation completed we have found only some personnel we have found all personnel require medical assistance

Operation completed.

Operation completed. In accordance with annex 12 what does the ground air visual signal code ++ used ?

Question 28-13 : We have found only some personnel require medical assistance operation completed we have found all personnel

We have found only some personnel.

We have found only some personnel. Search and rescue during the hours of daylight which of the following signals ?

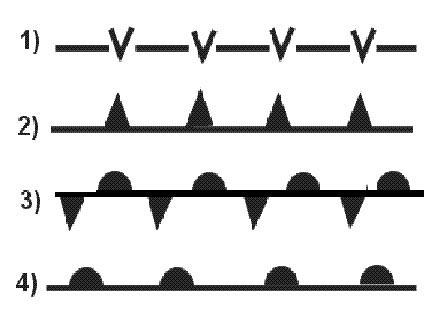

Question 28-14 : Rocking the aircraft`s wings circling the ground signals at least once flashing on and off twice the aircraft`s landing lights or if not so equipped its navigation lights overflying the ground signals twice on a north south heading

According to icao annex 12 'emergency phase' means… ?

Question 28-15 : Uncertainty phase alert phase or distress phase hazard phase warning phase or emergency phase uncertainty phase only distress phase only

Uncertainty phase, alert phase, or distress phase.

Uncertainty phase, alert phase, or distress phase. According to icao annex 12 what does rescue coordination centre mean ?

Question 28-16 : A unit responsible for promoting efficient organisation of search and rescue services and for coordinating the conduct of search and rescue operations within a search and rescue region a unit performing distress monitoring communication coordination and search and rescue functions initial medical assistance or medical evacuation through the use of public and private resources including cooperating aircraft vessels and other craft and installations a mobile resource composed of trained personnel and provided with equipment suitable for the expeditious conduct of search and rescue operations a unit retrieving persons in distress providing for their initial medical or other needs and delivering them to a place of safety

What ground air visual signal can survivors use to tell an aircraft they are ?

Question 28-17 : An arrow pointing in that direction a letter 'v' a letter 'y' triple 'x'

An arrow pointing in that direction.

An arrow pointing in that direction. Icao annex 12 defines the state of registry as the state… ?

Question 28-18 : On whose register the aircraft is entered where the aircraft is based in which the aircraft operator is registered on whose the certificate of registry of the aircraft is entered

On whose register the aircraft is entered.

On whose register the aircraft is entered. Which one of the following examples indicates an 'uncertainty phase' situation ?

Question 28-19 : When the position of an aircraft is uncertain when there is a potential for a collision when an aircraft has experienced a technical malfunction when an aircraft is known to be in an emergency situation

When the position of an aircraft is uncertain.

When the position of an aircraft is uncertain. Member states should introduce specific security measures for the air transport ?

Question 28-20 : Deportees inadmissible persons and persons in lawful custody deportees and persons in lawful custody only none of the answers is correct deportees and persons in lawful custody only

Deportees, inadmissible persons and persons in lawful custody.

Deportees, inadmissible persons and persons in lawful custody. An aircraft which is being subjected to unlawful interference hijacked and is ?

Question 28-21 : Continue at an altitude that differs from the semi circular rule with 1000 feet when above fl 290 and 500 feet when lower than fl 290 as soon as possible commence emergency descent in order minimize the difference between cabin pressure and outside pressure fly the emergency triangle declare an emergency

Continue at an altitude that differs from the semi-circular rule with 1000 feet when above fl 290 and 500 feet when lower than fl 290.

Continue at an altitude that differs from the semi-circular rule with 1000 feet when above fl 290 and 500 feet when lower than fl 290. Each state of icao annex 17 shall ensure the establishment of a security ?

Question 28-22 : At each airport only for istrative staff of airport that is common for all airports within state for every airline operating in the state

At each airport.

At each airport. The aircraft commander when he has reasonable grounds to believe that a person ?

Question 28-23 : May deliver such person to the competent authorities may request such person to disembark may require the assistance of passengers to restrain such person may not require or authorise the assistance of other crew members

May deliver such person to the competent authorities.

May deliver such person to the competent authorities. The icao annex 17 comprise rules in order to establish security measures for ?

Question 28-24 : Cabin baggage checked baggage cargo and other goods access control and airport design and baggage cabin baggage checked baggage cargo and other goods cabin baggage and checked baggage

Cabin baggage, checked baggage, cargo and other goods, access control and airport design.

Cabin baggage, checked baggage, cargo and other goods, access control and airport design. The national civil aviation security programme shall be established by ?

Question 28-25 : Each contracting state icao and other organisations including the contracting state concerned ecac icao

Each contracting state.

Each contracting state. When a member state allows police officers security staff bodyguards or other ?

Question 28-26 : Prior notification by the state of embarcation to the foreign state in which the weapons will be carried on the airport of arrival and notification of the pilot in command of a decision to permit a weapon to be carried on board his aircraft notification of the pilot in command of a decision to permit a weapon to be carried on board his aircraft only agreement between the state of embarcation and the state of destination agreement between the state of embarcation and the airport of arrival

Prior notification by the state of embarcation to the foreign state in which the weapons will be carried on the airport of arrival and notification of the pilot in command of a decision to permit a weapon to be carried on board his aircraft.

Prior notification by the state of embarcation to the foreign state in which the weapons will be carried on the airport of arrival and notification of the pilot in command of a decision to permit a weapon to be carried on board his aircraft. When an aircraft subjected to an unlawful interference has landed it shall ?

Question 28-27 : Two aforementioned states each state whose citizens suffered fatalities or injuries each state whose citizens were detained as hostages each state whose citizens are known to be on board the aircraft and the icao two aforementioned states each state whose citizens suffered fatalities or injuries each state whose citizens are known to be on board the aircraft and the icao two aforementioned states and the icao two aforementioned states each state whose citizens suffered fatalities or injuries on board the aircraft and the icao

Two aforementioned states, each state whose citizens suffered fatalities or injuries, each state whose citizens were detained as hostages, each state whose citizens are known to be on board the aircraft and the icao.

Two aforementioned states, each state whose citizens suffered fatalities or injuries, each state whose citizens were detained as hostages, each state whose citizens are known to be on board the aircraft and the icao. When mixing or contact does take place between passengers subjected to security ?

Question 28-28 : The passengers concerned and their cabin baggage shall be re screened before boarding an aircraft only the passengers cabin baggage are to be re screened the persons not subjected to security control shall be identified only the passengers are to be re screened

The passengers concerned and their cabin baggage shall be re-screened before boarding an aircraft.

The passengers concerned and their cabin baggage shall be re-screened before boarding an aircraft. Security measures apply to ?

Question 28-29 : Airport design flight safety domestic flights foreign aircrafts

Airport design.

Airport design. An area suitable for the parking of an aircraft which is know or believed to be ?

Question 28-30 : 100 m 500 m 75 m 200 m

100 m.

100 m. Who is helping the state provide security for the airports ?

Question 28-31 : Airport security committee local police department air force european union safety delegate

Airport security committee.

Airport security committee. Definition of security the icao annex 17 is a combination of measures ?

Question 28-32 : And human and material resources intended to safeguard civil aviation against acts of unlawful interference intended to safeguard passengers against acts of unlawful interference and human and material resources intended to improve aviation safety intended to reduce acts of unlawful interference

And human and material resources intended to safeguard civil aviation against acts of unlawful interference.

And human and material resources intended to safeguard civil aviation against acts of unlawful interference. What instructions would be given to an aircraft subject to unlawful ?

Question 28-33 : Directed to an isolated parking position directed to park in a normal terminal so the passengers could be offloaded with maximum efficiency directed to park on the runway directed to a normal terminal so the hi jackers would believe everything was normal

Directed to an isolated parking position.

Directed to an isolated parking position. If an aircraft subjected to an act of unlawful seizure has landed on its ?

Question 28-34 : 1 3 1 2 3 1 2 2

1, 3.

1, 3. Which of the following statements is correct concerning the flight crew ?

Question 28-35 : This door shall be capable of being locked this door must be made of a fire proof material this door shall be marked as an emergency access and be kept clear of obstructions at all times this door must resist to small arms fire and grenade shrapnel for at least 5 minutes

This door shall be capable of being locked.

This door shall be capable of being locked. In all aeroplanes which are equipped with a flight crew compartment door this ?

Question 28-36 : The time all external doors are closed following embarkation until any such door is opened for disembarkation at engines start up until shut down after the flight at line up for take off until the beginning of taxiing on the taxiway after landing commencement of pushback

The time all external doors are closed following embarkation until any such door is opened for disembarkation.

The time all external doors are closed following embarkation until any such door is opened for disembarkation. During the approach the gpws has activated and the pilot received a 'pull up' ?

Question 28-37 : Serious incident accident serious accident incident

Serious incident.

Serious incident. After landing while taxiing the landing gear sinks into a hole no person gets ?

Question 28-38 : This is an accident the crew must follow the procedure relevant to this case this is an incident the pilot in command must report it to the airport authority within the next 48 hours this is a technical incident since there is no person injured and the flight is terminated a damage report has to be made out for the respective insurance company this is an irregularity in the operation the crew must inform the operator of the aerodrome and establish a report

This is an accident. the crew must follow the procedure relevant to this case.

This is an accident. the crew must follow the procedure relevant to this case. The aircraft has made a complete stop on the apron when leaving the aircraft ?

Question 28-39 : An accident and the crew must follow the procedure relevant to this case an irregularity in passenger handling and the handling agent must inform their insurance company an incident and the pilot in command must report it to the airport authority within 48 hours a matter of passenger insurance and the airport operator or the company in charge of the handling shall write a report for the insurance company

An accident and the crew must follow the procedure relevant to this case.

An accident and the crew must follow the procedure relevant to this case. What is the objective of the investigation of an accident or incident according ?

Question 28-40 : To prevent accidents and incidents to apportion blame for the subsequent legal proceedings to determine the operator`s liability to determine the aircraft manufacturer`s liability

To prevent accidents and incidents.

To prevent accidents and incidents. ~

Exclusive rights reserved. Reproduction prohibited under penalty of prosecution.

1079 Free Training Exam Other source study: Furious atpl examen 28